I-SCM2 Series Centrifugal Uhlobo Lwephampu Yamanzi

Isicelo

Lawa maphampu afanele ukuphatha amanzi ahlanzekile angenazo izinhlayiya eziqhumayo noketshezi olungenalo udlame lwamakhemikhali ezingxenyeni zephampu.

Zithembeke ngokwedlulele, zilula ukuzisebenzisa ezithule futhi azinakekelwa, zithola ukusetshenziswa okuningi ezindlini nasezindaweni zomphakathi, futhi ikakhulukazi ukusatshalaliswa okuzenzakalelayo kwamanzi asuka emathangeni amancane naphakathi nendawo, ukudlulisa amanzi, ukuchelela izingadi.njll.

Izimo zokusebenza

Izinga lokushisa eliphezulu le-Fluid lifika ku-+60℃

I-Max Ambient Temperature efika ku-40℃

I-suction lift ifika ku-8m

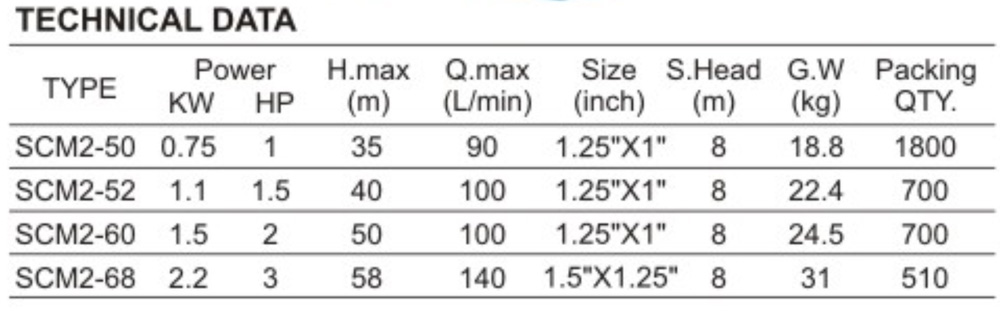

Idatha yobuchwepheshe

Incazelo Yobuchwepheshe

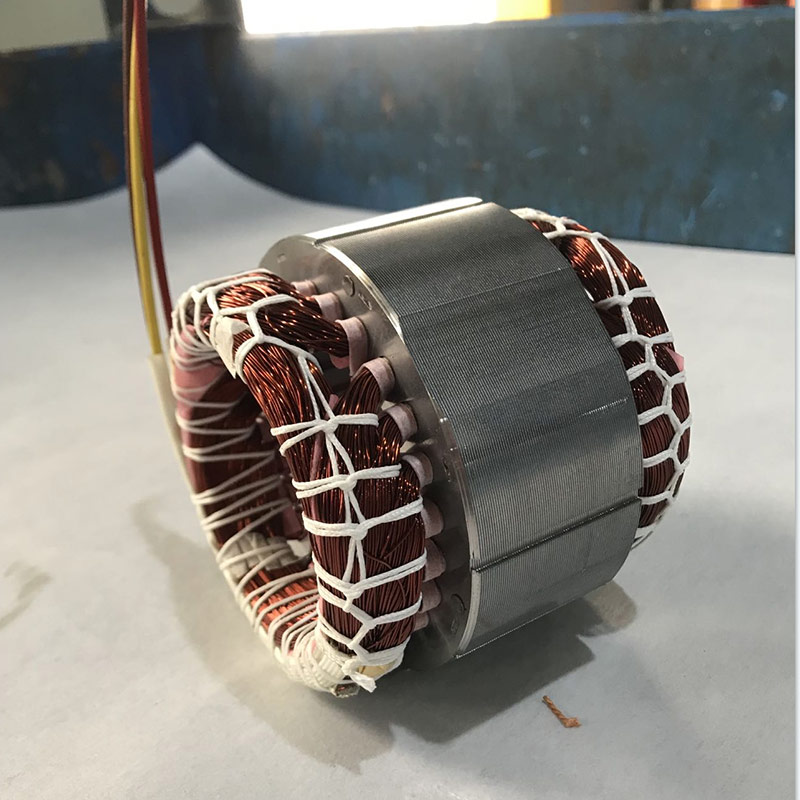

1. injini

Ikhoyili yemoto yethusi egcwele izintambo zomshini, i-stator entsha, ukulawulwa okuhle kokukhuphuka kwezinga lokushisa, ukusebenza okuzinzile

(i-aluminium evala ucingo kanye nobude obuhlukile be-stator bungenziwa ngokuya ngalokho ikhasimende elikucelayo)

2. I-Impeller

I-Twin Brass impellers (ama-impeller amabili asebenzayo)

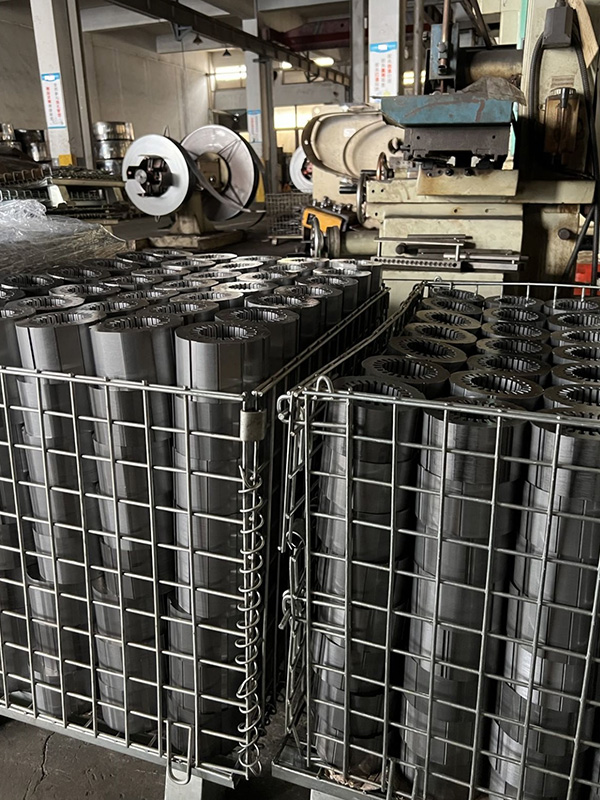

3. I-rotor ne-shaft

Ubufakazi bomswakama ongaphezulu, ukwelashwa kokugqwala

I-Carbon steel shaft noma i-304 shaft yensimbi engagqwali

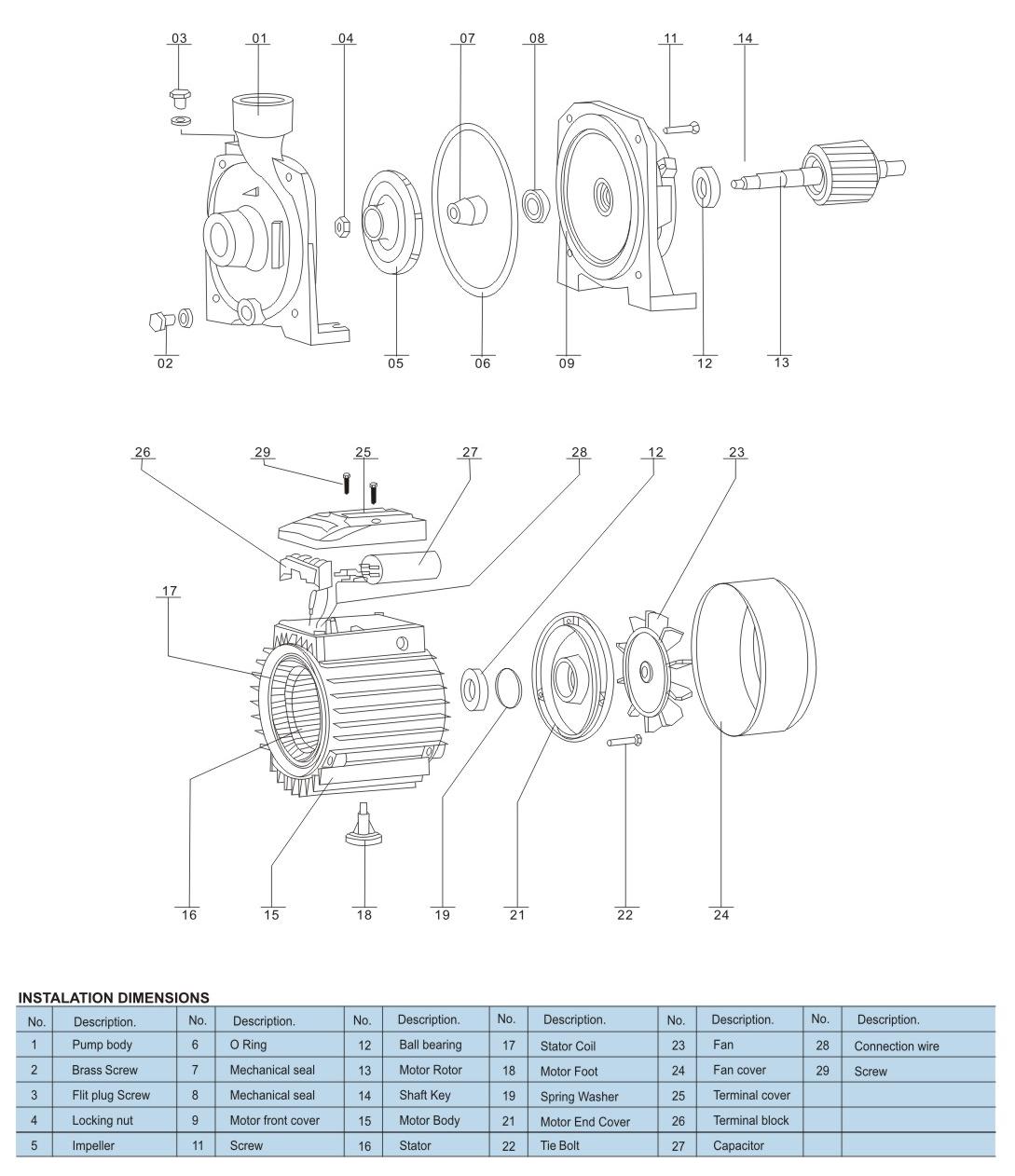

Ukubuka Okuqhume

Umugqa wokukhiqiza

Ikhwalithi yokulawula

bheka uhlelo lokuphathwa kwekhwalithi ISO 9001.

Ukuqala ngedizayini, ukuhlola, nokugunyazwa ngaphambi kokwamukelwa, kusukela kusampula ukuya ekuthengeni kwenqwaba

Ngaphambi kokungena endlini yethu yokugcina impahla, izinto zokwakha zabaphakeli bethu ziyahlolwa.

ukulungiselela imiyalelo yokusebenza kanye nesu lokulawula ikhwalithi.

Izinto zokuhlola ziyitholile ngesikhathi sokukhiqiza;ukuhlolwa kwendawo yesibili kwenziwa ngaphambi kokusabalalisa.

Umyalelo wokufaka

Amaphampu kufanele abekwe endaweni eyomile futhi enomoya omuhle enezinga lokushisa elingeqile ku-40 ° C (njengoba kuboniswe ku-Fig. A).Ukuze uvimbele ukudlidliza, iphampu kufanele iboshwe ngokuvikelekile kusetshenziswa amabhawudi afanelekile endaweni ezinzile neyisicaba.Ukusebenza kahle kwama-bearings kudinga ukukhwezwa okuvundlile kwepompo.Ububanzi bepayipi lokungenisa akumele bube buncane kunobunjini bokungena.Uma ukuphakama kokuthatha kungaphezu kwamamitha angu-4, ipayipi elinobubanzi obukhulu kufanele lisetshenziswe.Ububanzi bepayipi lokulethwa kufanele kukhethwe ngokusekelwe kuzinga lokugeleza elidingekayo kanye nokucindezela ezindaweni zokusuka.Ukuze ugweme ukuthuthukiswa kwezingidi zomoya, ipayipi lokungenisa kufanele lihlehliselwe kancane liye phezulu emlonyeni wokungena (njengoba kuboniswe ku-Fig. B).Kubalulekile ukuqinisekisa ukuthi ipayipi lokungena licwiliswe ngokuphelele futhi livalwe.

Ukupakisha

ibhokisi lebhokisi lempahla elihle, lenza ukwakheka kombala ogcwele, ngokuvikelwa kwegwebu ngaphakathi

Ezokuthutha

Impahla eyinqwaba ebaluleke kakhulu noma ukulayishwa kwesiqukathi esigcwele emachwebeni ase-Ningbo, e-Shanghai, nase-Yiwu.

Amasampula

Uma isampula libiza, kungase kube nenkokhelo;uma ufaka i-oda elisemthethweni, cabangela imbuyiselo yenkokhiso.

Ungahlola ukuthunyelwa kwesampula ngomhlaba, ulwandle, noma ngomoya ngendlela othanda ngayo.

Isikhathi sokukhokha

Ithemu ye-T/T: 20% idiphozi ngaphambi kwesikhathi, ibhalansi engu-80% iqhathaniswa nekhophi ye-bill of lading

Itemu le-L/C: ngokuvamile liyakhokhwa lapho libonwa

Itemu ye-D/P, idiphozithi engu-20% kusengaphambili, ibhalansi engu-80% ye-D/P lapho uyibona

Umshwalense wesikweletu: 20% wenkokhelo ephansi kuqala, ibhalansi engu-80% ye-OA ezinsukwini ezingama-60 ngemuva kokuba inkampani yomshwalense isinikeze umbiko

Iwaranti

Ukusebenzisa inombolo ye-serial kuyindlela enhle yokulandelela iphampu nokuphendula imibuzo yabasebenzisi.Isikhathi sewaranti yomkhiqizo yizinyanga eziyi-13 kusukela ngosuku lokukhokha.Uma noma yiziphi izinkinga zekhwalithi yokukhiqiza ziphakama phakathi nesikhathi sewaranti ehlobene nezingxenye ezisengozini nezingxenye, Umphakeli uzoba nesibopho sokuhlinzeka ngezingxenye ezishintshayo ngemva kokuba izinhlangothi zombili ziluqinisekisile udaba.Ikhotheshini yomkhiqizo ejwayelekile ayifaki izindleko zanoma yiziphi izesekeli.Phakathi nesikhathi sewaranti, ngokusekelwe empendulweni yomsebenzisi, sizoxoxisana ukuze sinikeze izingxenye ezisengozini ukuze zilungiswe, futhi ezinye izingxenye kungase kudingeke zithengwe ngesinxephezelo.Noma yiziphi izinkinga zekhwalithi zingabikwa ukuze kwenziwe ucwaningo futhi kuxoxiswane ngazo.