QB Series Peripheral Uhlobo Amanzi Pump

Isicelo

ilungele ukumpompa amanzi ahlanzekile, njengokuphakelwa kwamanzi aphuma emithonjeni, emachibini njll. Ilungele futhi ukukhuphula umfutho wamanzi, ukulima ingadi kanye nohlelo lokuphakela amanzi oluzenzakalelayo uma ihlanganiswe nezinye izinto ezisetshenziswayo.

ikakhulukazi ukusatshalaliswa kwamanzi okuzenzakalelayo esuka emathangeni ashubile, izingadi zokunisela kanye nokukhulisa umfutho wamanzi onganele.

Lawa maphampu kufanele afakwe endaweni evaliwe, evikelekile esimweni sezulu.

Izimo zokusebenza

Izinga lokushisa eliphezulu le-Fluid lifika ku-+80℃

I-Max Pressure 10bar

I-Max Ambient Temperature efika ku-40℃

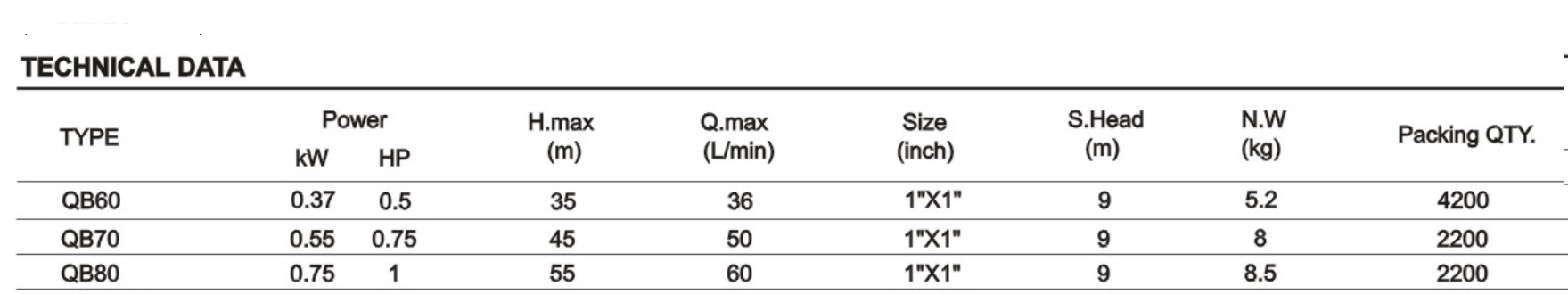

Idatha yobuchwepheshe

Incazelo Yobuchwepheshe

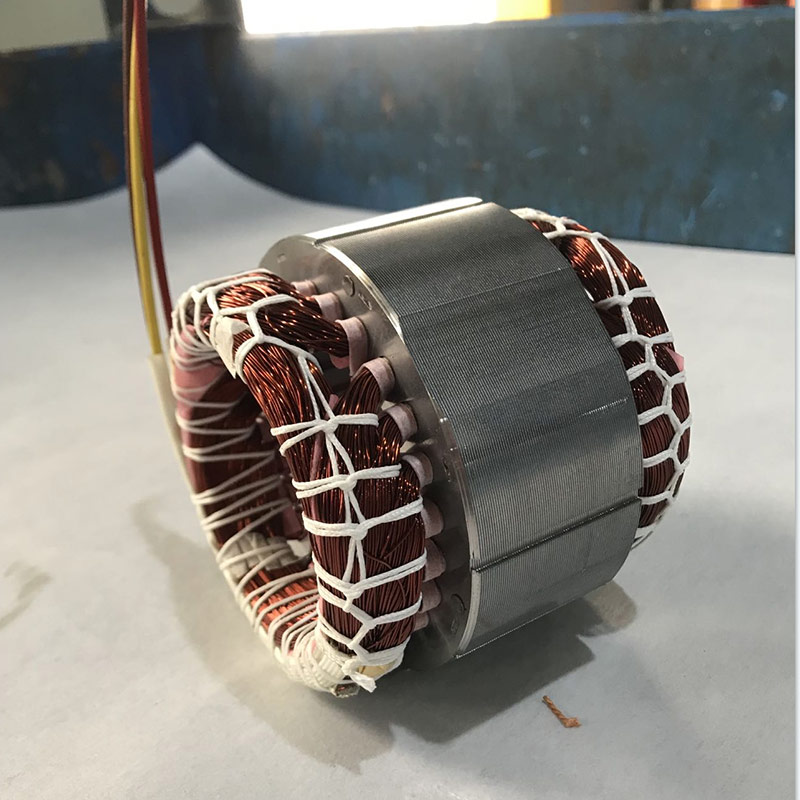

1. injini

100% intambo yethusi egcwele, izintambo zomshini, i-stator yezinto ezintsha, ukunyuka kwezinga lokushisa eliphansi, ukusebenza okuzinzile

(intambo ye-aluminium nobude obuhlukile be-stator eyenziwe ngokudinga kwakho)

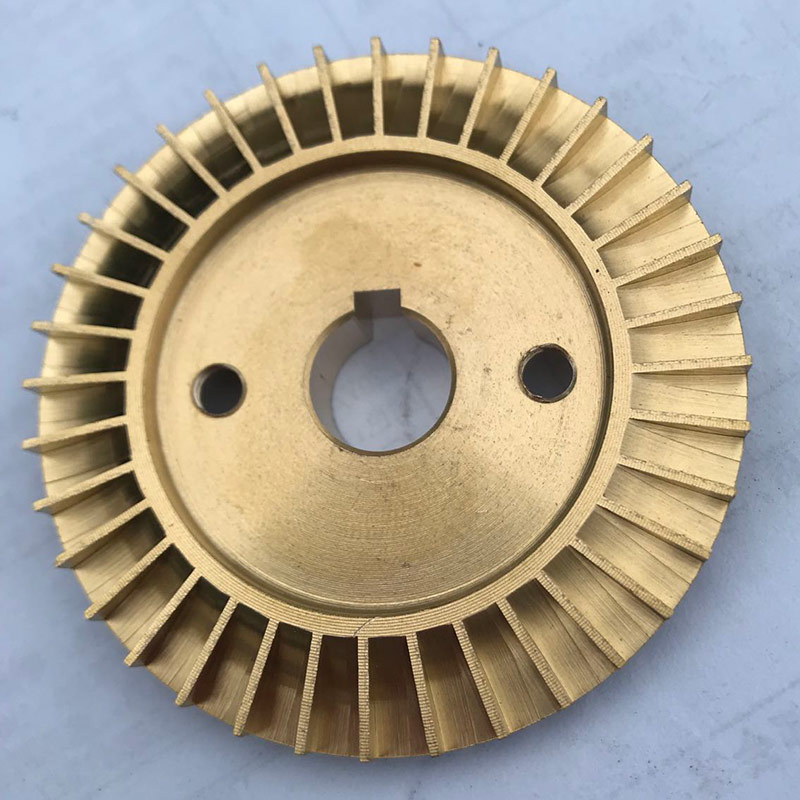

2. I-Impeller

Izinto zethusi njengezijwayelekile

Izinto zensimbi engagqwali ongakhetha kuzo

Izinto ze-aluminium ongakhetha kuzo

Izinto zepulasitiki ongakhetha kuzo

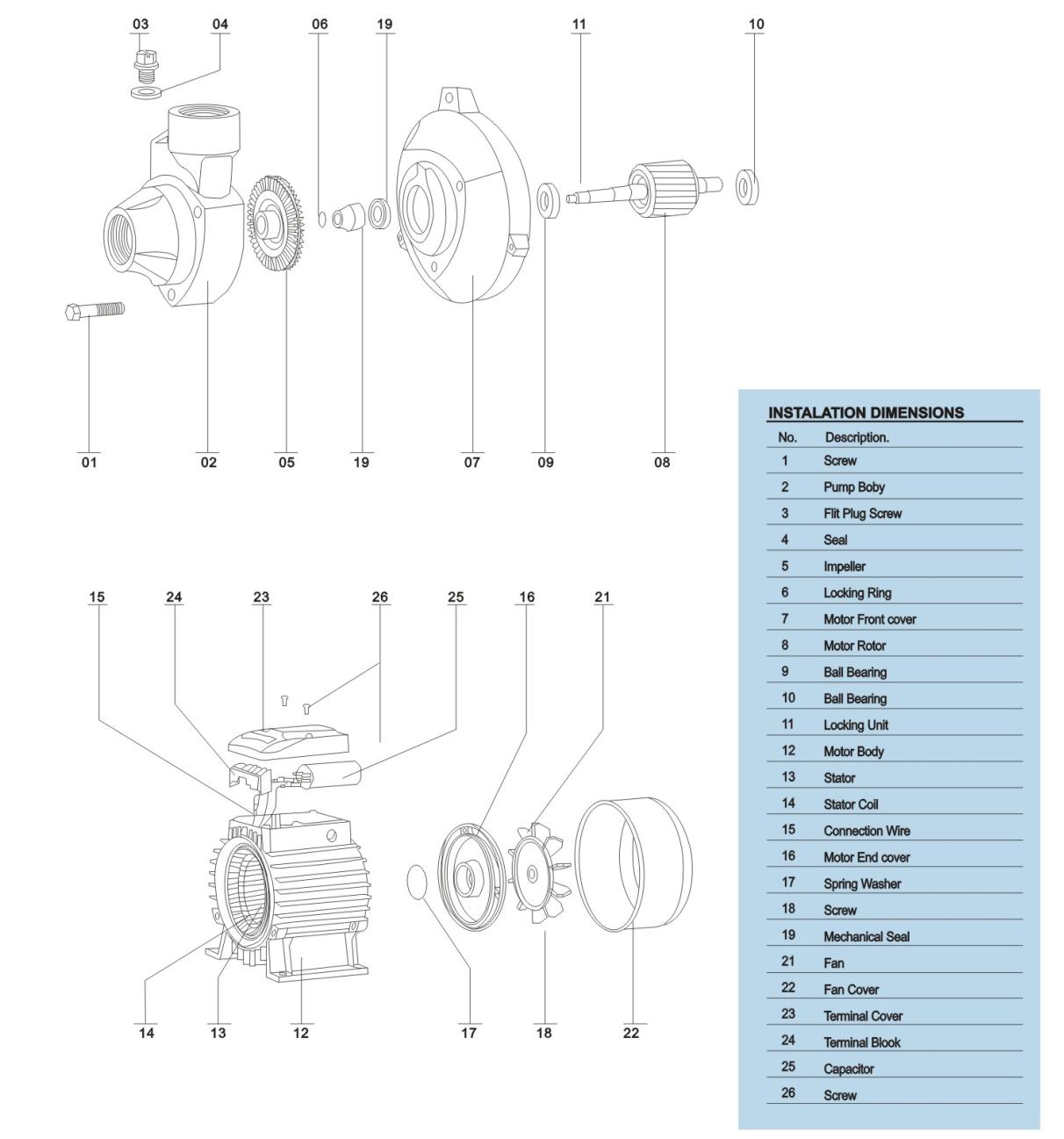

3. I-rotor ne-shaft

Ubufakazi bomswakama ongaphezulu, ukwelashwa kokugqwala

I-Carbon steel shaft noma i-304 shaft yensimbi engagqwali

Ukubuka Okuqhume

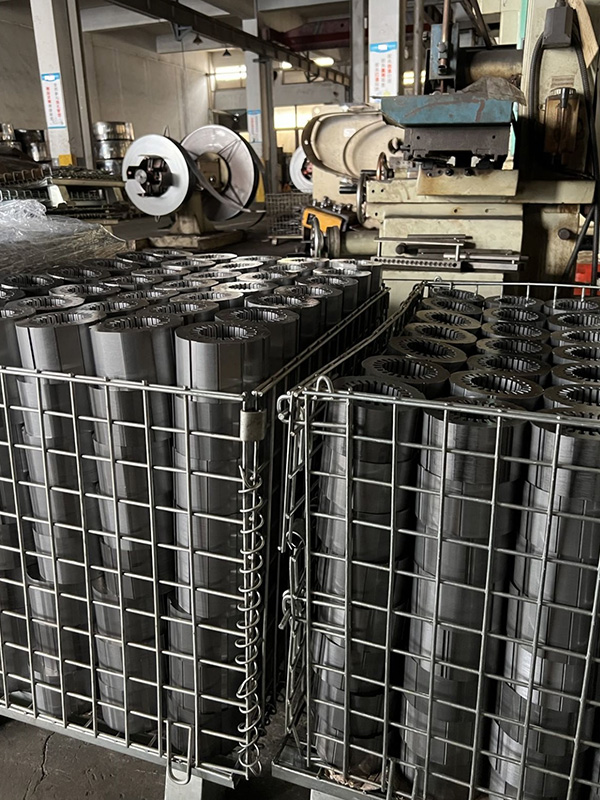

Umugqa wokukhiqiza

Ikhwalithi yokulawula

Landela isistimu yokuphatha ikhwalithi ye-ISO9001.

Dizayina ekuqaleni ngokuhlola nokuhlola ngaphambi kokwamukelwa, ukusuka kusampula ukuya ekuthengeni kwenqwaba.

Ukuhlolwa kwezinto ezibonakalayo zabahlinzeki bethu ngaphambi kokungena endlini yethu yokugcina impahla.

Ukwenza uhlelo lokulawula ikhwalithi, kanye nokulungiselela imiyalelo yokusebenza.

Kutholwe imishini yokuhlola ngesikhathi sokukhiqiza, i-Spot hlola futhi ngaphambi kokuthunyelwa.

Umyalelo wokufaka

Amaphampu kufanele afakwe endaweni enomoya owomile enezinga lokushisa elingekho ngaphezu kuka-40℃(Fig.A).Lungisa iphampu endaweni eyisicaba eqinile usebenzisa amabhawodi afanelekile ukuze ugweme ukudlidliza.Iphampu kufanele ifakwe endaweni evundlile amathoniLi ukuthi ama-bearings asebenza ngendlela efanele.Ububanzi bepayipi lokungenisa akumele bube buncane kunalelo lwebhu lokungenisa.Uma ubude bokungena kudlula amamitha angu-4, sebenzisa ipayipi elinobubanzi obukhudlwana. Ububanzi bepayipi lokulethwa kufanele bukhethwe ukuze buvumelane nezinga lokugeleza nokucindezela okudingekayo ezindaweni ezisuka kuzo. ukwakheka kwezingidi zomoya (Fig.B) .Qinisekisa ukuthi ipayipi lokungenisa lingenawo umoya ngokuphelele futhi licwiliswe emanzini okungenani isigamu semitha ukuze ugweme ukwakheka kwama-vortex.Njalo faka i-valve yonyawo ekugcineni kwepayipi lokungena.Kutuswa ukufaka i-valve engabuyi phakathi komlomo wokulethwa kanye ne-valve yesango yokulungiswa kwesilinganiso sokugeleza ukuze kugwenywe ukushaywa kwamanzi okuyingozi uma kwenzeka iphampu ima kungazelelwe.Lesi silinganiso siyimpoqo uma ikholomu yamanzi okulethwa ingaphezu kwamamitha angama-20.

Amapayipi kufanele afakwe kithi kubakaki abahlobene (Fig. C) ukugwema ukudlulisa ingcindezi emzimbeni wephampu.Qaphela ukuthi ungalimazi noma iyiphi ingxenye ngokucindezela amapayipi uma uwafaka.

Ukupakisha

Dizayina Umbala webhokisi lebhokisi lebhokisi elingaphakathi elinegwebu lokupakisha, elinebhokisi elikhulu noma cha

Cishe ama-4000pcs alingana nesitsha sonke esingu-20”.

Ezokuthutha

Ilayisha isiqukathi echwebeni lase-Ningbo njengechweba lokusuka umkhumbi.

Ezinye izindlela nazo zilungile, njengechweba laseShanghai, i-Yiwu njalonjalo

Amasampula

Yenza isampula yamahhala yokuhlola kwakho, cela ukukhokhiswa okuthile uma amasampula amaningi kakhulu, futhi uxoxe ngembuyiselo yenkokhiso uma wenza i-oda elisemthethweni kamuva.

Thumela isampula ngomhlaba, ulwandle, ngisho nezokuthutha emoyeni ngokuthanda kwakho.

Isikhathi sokukhokha

Ithemu ye-T/T: 20% idiphozithi kusengaphambili, ibhalansi engu-80% uma iqhathaniswa nekhophi yomthwalo wempahla

Itemu L/C: ngokuvamile L/C lapho ubona, isikhathi eside sokuxoxa.

Ithemu ye-D/P, idiphozithi engu-20%, ibhalansi engu-80% ngokubona kwe-D/P

Umshwalense wesikweletu: 20% idiphozi engaphambili, 80% ibhalansi ye-OA ezinsukwini ezingama-60 ngemuva kokuba inkampani yomshwalense isinikeze umbiko, isikhathi eside sokuxoxa

Iwaranti

Isikhathi sewaranti yomkhiqizo yizinyanga eziyi-13 (sibalwe kusukela ngosuku lokulayishwa kwemali).Ngokuvumelana nezingxenye ezisengozini efanelekile kanye nezingxenye, uma kunenkinga yekhwalithi yokukhiqiza okungekaMhlinzeki ngesikhathi sewaranti, Umphakeli uzoba nesibopho sokuhlinzeka noma ukushintsha izingxenye zokulungisa ngemva kokuhlonzwa okuhlanganyelwe kanye nokuqinisekiswa kwezinhlangothi zombili.Ikhotheshini yemikhiqizo evamile ayifaki noma iyiphi ingxenye yezesekeli.Ngesikhathi sewaranti, ngokwempendulo yangempela, sizoxoxisana ukuze sinikeze izingxenye ezisengozini yokunakekelwa, futhi ezinye izingxenye zingadinga ukuthengwa ngesinxephezelo.Noma yiziphi izinkinga zekhwalithi zingabikwa ocwaningweni nasekuxoxisaneni.