I-JET Series Self Priming Uhlobo Lwephampu Yamanzi

Incazelo Yomkhiqizo

I-JET-S

I-JET-M

I-JET-L

Isicelo

Amanzi ahlanzekile noketshezi olungeyona ingozi ngamakhemikhali ezingxenyeni zephampu kungampontshwa kusetshenziswa la maphampu.

Zifaneleka kakhulu izinhlelo zokusebenza zasekhaya njengamathangi okuhlinza anosayizi omaphakathi, izingadi zokunisela, njll. ngoba zithembeke kakhulu, azibizi, futhi kulula ukuzisebenzisa.

Lawa maphampu kufanele amiswe endaweni emboziwe evikelekile ezintweni.

I-valve yonyawo noma i-valve engabuyi kufanele ihlale ifakwe embotsheni yokudonsa, uma kwenzeka.

Izimo zokusebenza

Izinga lokushisa eliphezulu le-Fluid lifika ku-+60℃

I-Max Ambient Temperature efika ku-40℃

I-suction lift ifika ku-8m

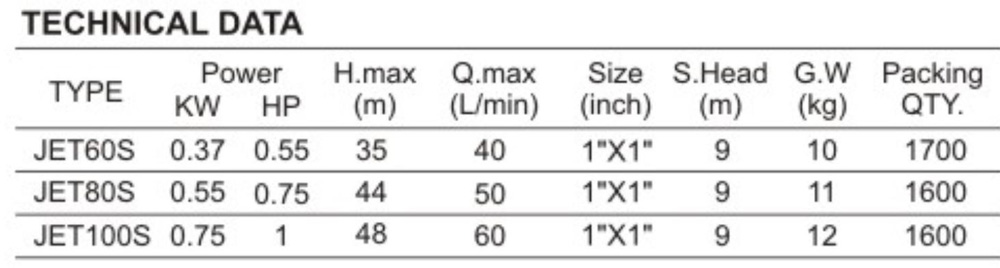

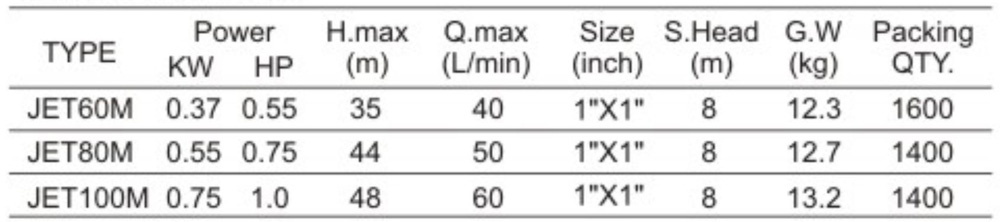

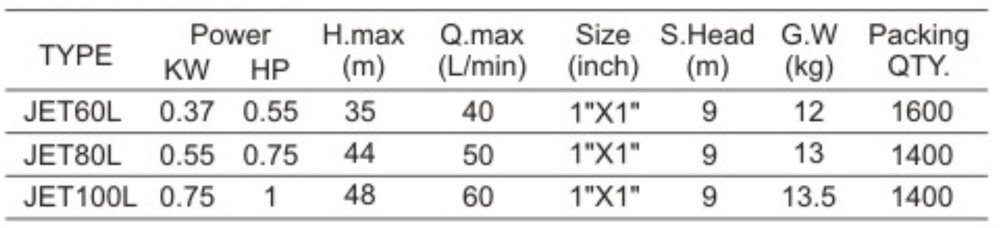

Idatha yobuchwepheshe

Incazelo Yobuchwepheshe

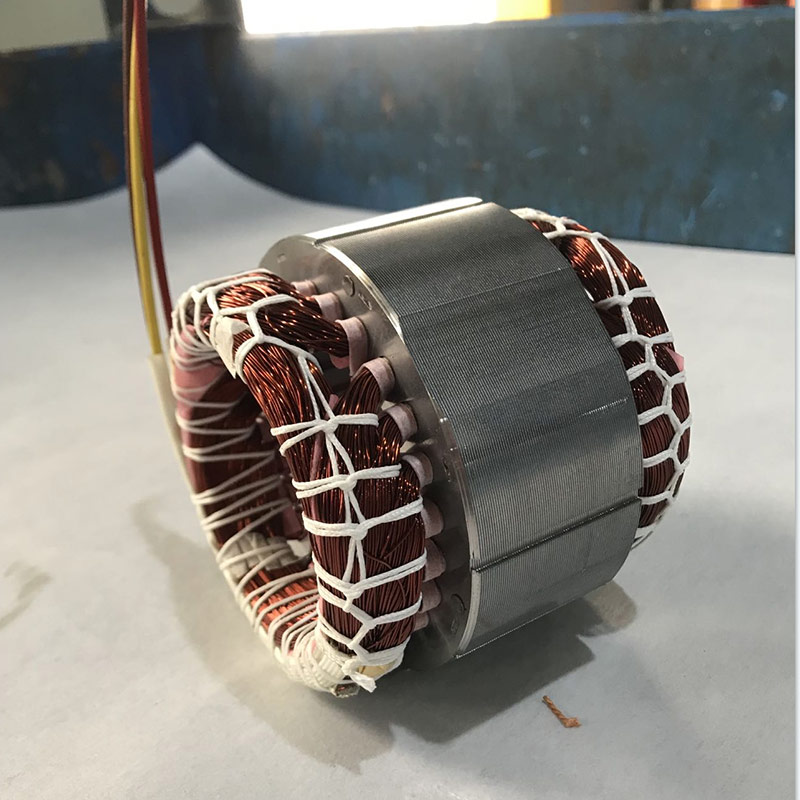

1. injini

I-100% egcwele i-coil winding motor motor, izintambo zomshini, i-stator entsha yezinto ezibonakalayo, ukukhuphuka okuhle kwezinga lokushisa, ukusebenza okuzinzile

(i-aluminium wire motor oyithandayo iyatholakala, ubude be-stator benziwe njengoba udinga ngekhanda elihlukile nokugeleza)

2. I-Impeller

Izinto zethusi ziwukucushwa okujwayelekile

Insimbi engagqwali yayingenziwa

Izinto ze-aluminium zingenziwa

Kungenziwa izinto zepulasitiki

3. I-rotor ne-shaft

Ubufakazi bomswakama ongaphezulu, ukwelashwa kokugqwala

I-Carbon steel shaft noma i-304 shaft yensimbi engagqwali

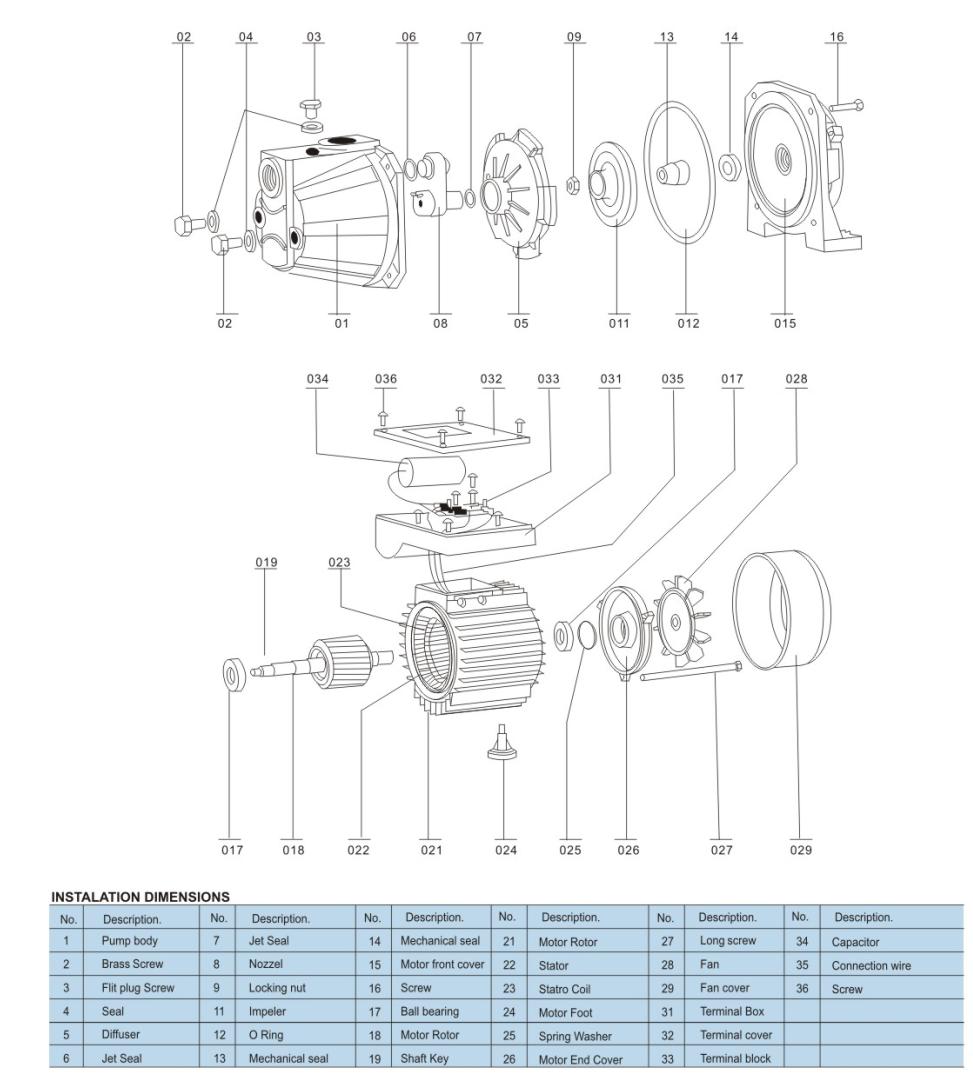

Ukubuka Okuqhume

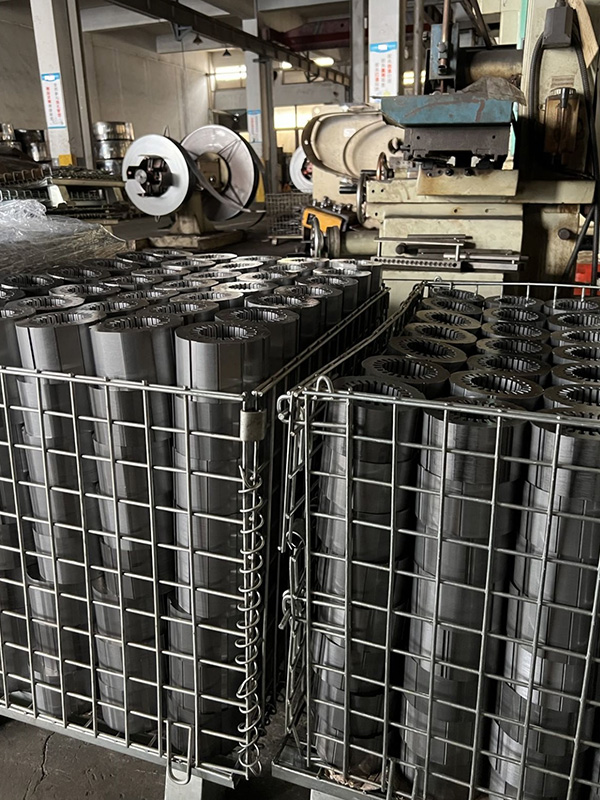

Umugqa wokukhiqiza

Ikhwalithi yokulawula

landela uhlelo lokuphathwa kwekhwalithi ye-ISO 9001.Kusukela ekukhulelweni kuya ekuhlolweni kuya ekuvunyweni ngaphambi kokwamukelwa, kusukela kusampula kuya ekuthengeni kwenqwaba Izinto ezivela kubathengisi bethu ziyahlolwa ngaphambi kokungena endlini yethu yokugcina impahla.ukwakha uhlelo lokulawula ikhwalithi kanye nemiyalelo yokusebenza.Kutholwe ngemishini yokuhlola ngesikhathi sokukhiqiza, futhi ukuhlolwa kwendawo yesibili kwenziwa ngaphambi kokusatshalaliswa.

Umyalelo wokufaka

Indawo lapho amaphampu atholakala khona idinga ukushaywa umoya futhi yome, izinga lokushisa elizungezile elingekho ngaphezu kuka-40 ° C (Fig.A).Vikela iphampu ngamabhawodi alungile endaweni eqinile, eyisicaba ukuze uvimbele ukudlidliza.Iphampu kufanele ibekwe ngokuvundlile ukuze ama-bearings asebenze kahle.Ububanzi bombhobho wokungenisa abukwazi ukuba buncane kunobunjini bokungena.Uma ukuphakama kokuthatha kungaphezu kwamamitha angu-4, sebenzisa ipayipi elinobubanzi obukhulu.Ububanzi bepayipi lokulethwa kufanele bukhethwe ukuze buhambisane nezinga lokugeleza nokucindezela okudingekayo ezindaweni ezisuka kuzo.Ipayipi elingenisayo kufanele libheke phezulu kancane libheke emlonyeni wokungena ukuze kuvinjwe ukwakheka kwezingidi zomoya (Fig.B).Qinisekisa ukuthi ipayipi lokungenisa livaliwe futhi licwiliswe ngokuphelele.

Ukupakisha

Ibhokisi lebhokisi njengento evamile yokupakisha, ingaba umklamo ogcwele wombala.

Ibhokisi lezinkuni njengenye inketho, enamandla kakhulu, isivikelo esingcono.

Ezokuthutha

Ukulayisha okubalulekile kumachweba we-Ningbo, Shanghai, kanye nechweba le-Yiwu.Ningbo kusilungele kakhulu.

Isitsha esigcwele sezimpahla ngobuningi

Amasampula

Xoxa ngokunikeza isampula yamahhala, ezinye zingakhokhiswa kuqala, uma ufaka i-oda elisemthethweni, cabangela imbuyiselo yenkokhiso.

Ungahlola ukuthunyelwa kwesampula ngomhlaba, ulwandle, noma ngomoya ngendlela othanda ngayo.

Isikhathi sokukhokha

Ithemu ye-T/T: 20% idiphozi ngaphambi kwesikhathi, ibhalansi engu-80% iqhathaniswa nekhophi ye-bill of lading

Itemu le-L/C: khetha i-L/C lapho ubona

Itemu ye-D/P, idiphozithi engu-20% kusengaphambili, ibhalansi engu-80% ye-D/P lapho uyibona

Umshwalense wesikweletu: 20% wediphozithi kusengaphambili, 80% ibhalansi ye-OA izinsuku ezingama-60 ngesiqinisekiso esivela enkampanini yomshwalense.

Iwaranti

Ukwenza inombolo ye-serial ku-nameplate ukuze ulandele isevisi yangemuva kokuthengisa, futhi ulandelele isikhathi sewaranti, gxila empendulweni yekhasimende.

Izinyanga eziyi-13 kusukela ngosuku lokukhokhiswa kwempahla njengesikhathi sewaranti.Ngokuvumelana nezingxenye ezisengozini efanelekile kanye nezingxenye, uma kunenkinga yekhwalithi yokukhiqiza okungekaMhlinzeki ngesikhathi sewaranti, Umphakeli uzoba nesibopho sokuhlinzeka noma ukushintsha izingxenye zokulungisa ngemva kokuhlonzwa okuhlanganyelwe kanye nokuqinisekiswa kwezinhlangothi zombili.Ikhotheshini yemikhiqizo evamile ayifaki noma iyiphi ingxenye yezesekeli.Ngesikhathi sewaranti, ngokwempendulo yangempela, sizoxoxisana ukuze sinikeze izingxenye ezisengozini yokunakekelwa, futhi ezinye izingxenye zingadinga ukuthengwa ngesinxephezelo.Noma yiziphi izinkinga zekhwalithi zingabikwa ocwaningweni nasekuxoxisaneni.