I-CPM Series Centrifuagl Uhlobo Lwephampu Yamanzi

Isicelo

Lawa maphampu afanele ukuphatha amanzi ahlanzekile angenazo izinhlayiya eziqhumayo noketshezi olungenalo udlame lwamakhemikhali ezingxenyeni zephampu.

Zithembeke ngokwedlulele, zilula ukuzisebenzisa ezithule futhi azinakekelwa, zithola ukusetshenziswa okuningi ezindlini nasezindaweni zomphakathi, futhi ikakhulukazi ukusatshalaliswa okuzenzakalelayo kwamanzi asuka emathangeni amancane naphakathi nendawo, ukudlulisa amanzi, ukuchelela izingadi.njll.

Izimo zokusebenza

Izinga lokushisa eliphezulu le-Fluid lifika ku-+60℃

I-Max Ambient Temperature efika ku-40℃

I-suction lift ifika ku-8m

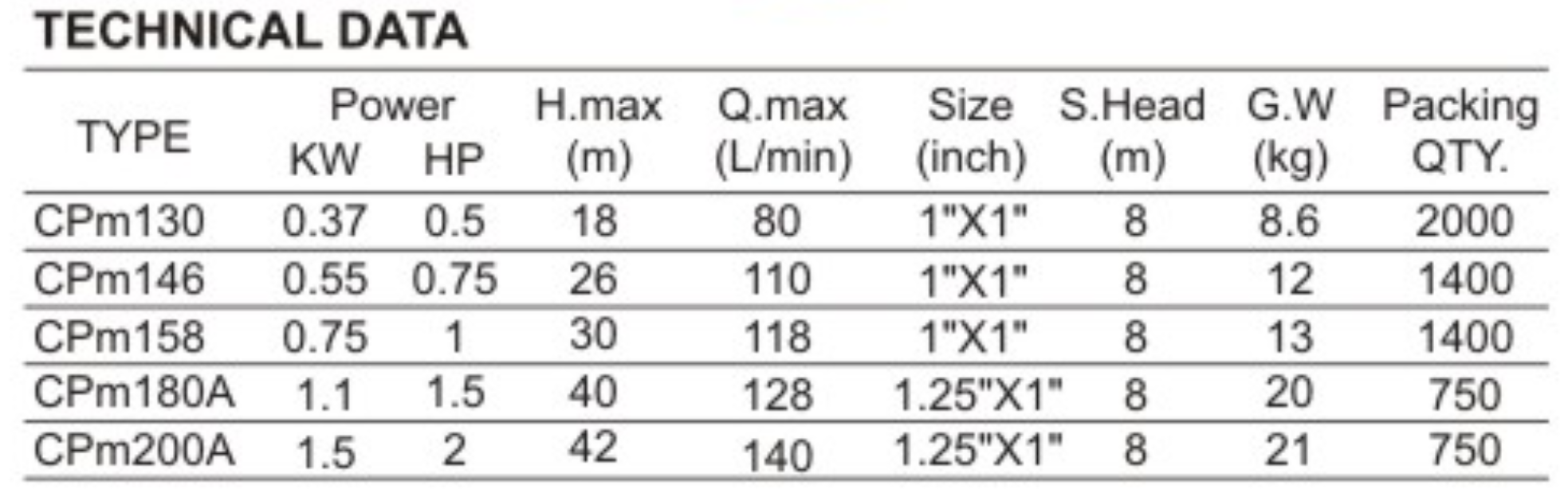

Idatha yobuchwepheshe

Incazelo Yobuchwepheshe

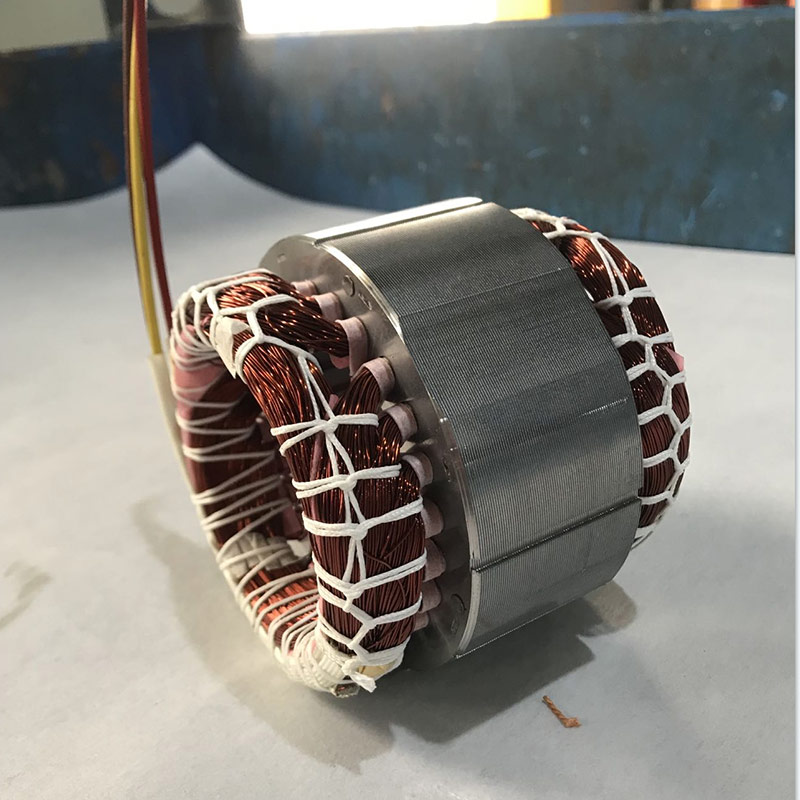

1. injini

100% ikhoyili yokusonta yethusi, izintambo zomshini, i-stator yezinto ezintsha, ukunyuka kwezinga lokushisa eliphansi, ukusebenza okuzinzile

(ikhoyili ye-aluminiyamu yokusonta ngokuzikhethela kwakho iyatholakala, ubude be-stator obuhlukile ngokukhetha kwakho)

2. I-Impeller

Izinto zethusi

Izinto zensimbi engagqwali

Izinto ze-aluminium

Izinto zepulasitiki

3. I-rotor ne-shaft

Ubufakazi bomswakama ongaphezulu, ukwelashwa kokugqwala

I-Carbon steel shaft noma i-304 shaft yensimbi engagqwali

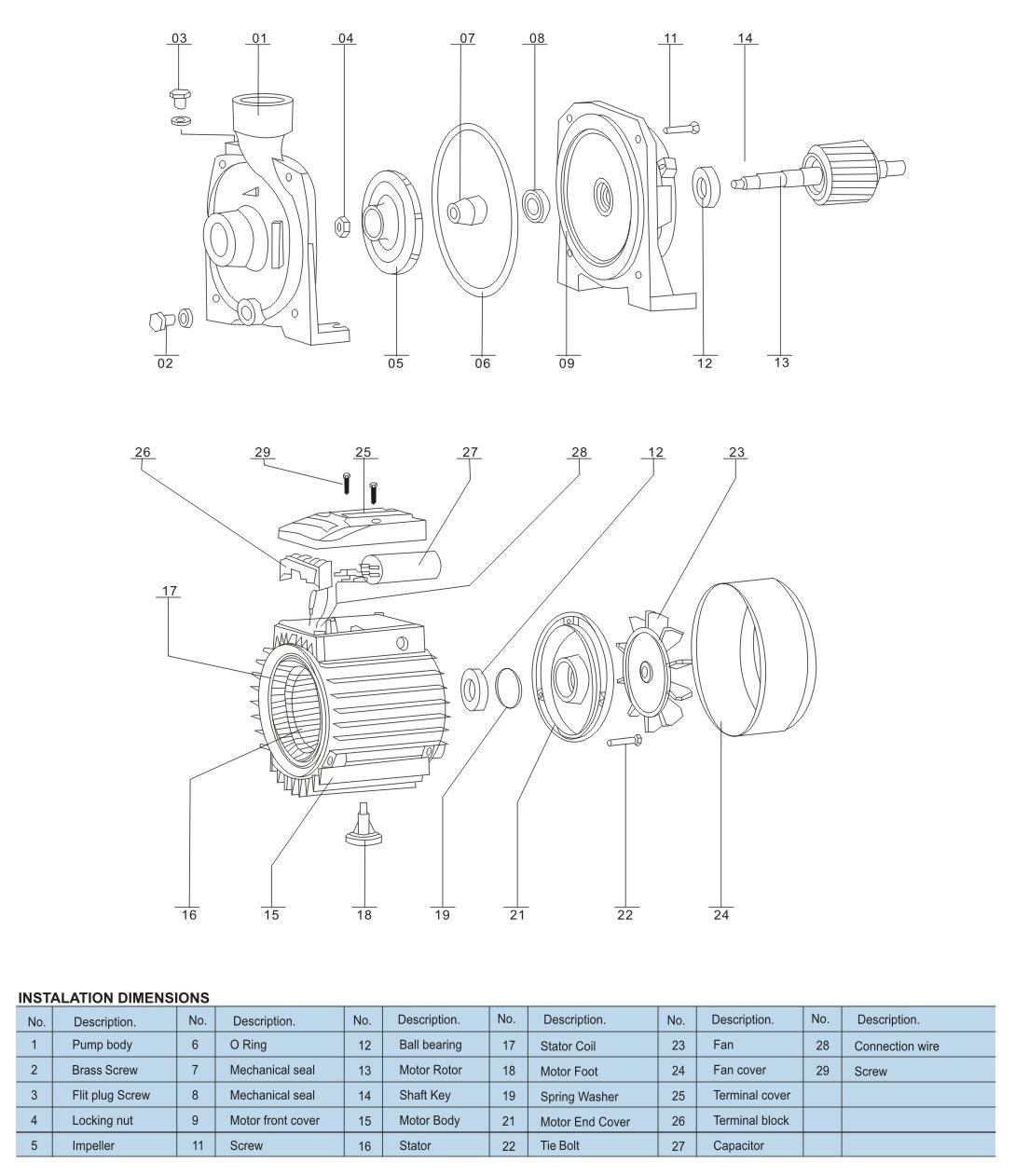

Ukubuka Okuqhume

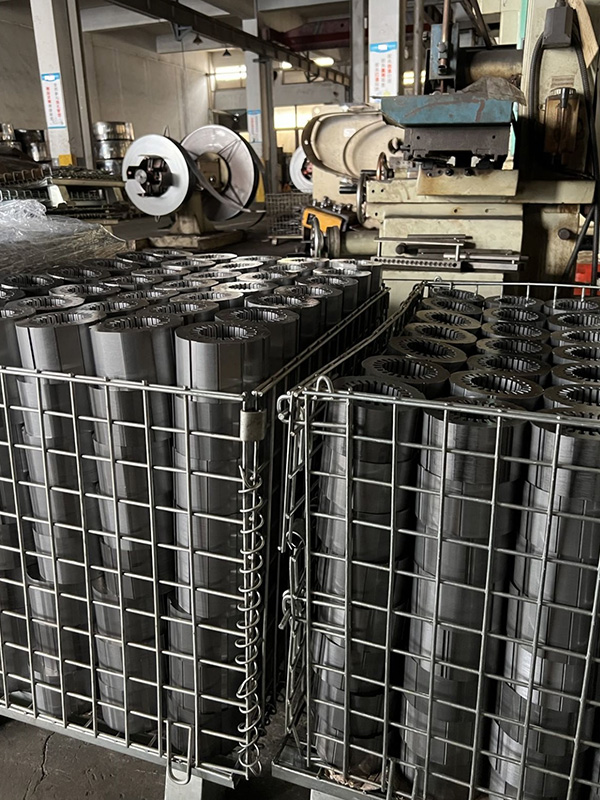

Umugqa wokukhiqiza

Ikhwalithi yokulawula

bheka uhlelo lokuphathwa kwekhwalithi ISO 9001.

Ukuqala ngedizayini, ukuhlola, nokugunyazwa ngaphambi kokwamukelwa, kusukela kusampula ukuya ekuthengeni kwenqwaba

Ngaphambi kokungena endlini yethu yokugcina impahla, izinto zokwakha zabaphakeli bethu ziyahlolwa.

ukulungiselela imiyalelo yokusebenza kanye nesu lokulawula ikhwalithi.

Izinto zokuhlola ziyitholile ngesikhathi sokukhiqiza;ukuhlolwa kwendawo yesibili kwenziwa ngaphambi kokusabalalisa.

Umyalelo wokufaka

Indawo yamaphampu kumele ifakwe umoya owomile futhi ibe nezinga lokushisa elingekho ngaphezu kuka-40°C (Fig.A).Ukuze uvimbele ukudlidliza, vikela iphampu usebenzisa amabhawudi afanele endaweni ezinzile, eyisicaba.Ukuqinisekisa ukuthi ama-bearings asebenza kahle, iphampu kufanele ifakwe ngokuvundlile.Ububanzi bepayipi lokungenisa abukwazi ukuba ngaphansi kwenjini yokungenisa.Sebenzisa ipayipi elinobubanzi obukhulu uma ubude bokungena bukhulu kunamamitha angu-4.Ububanzi bepayipi lokulethwa kufanele kukhethwe ukuze kufane nezinga lokugeleza nokucindezela okudingekayo ezindaweni ezisukayo.Ukuze uvimbele ukuthuthukiswa kwezingidi zomoya, ipayipi lokungenisa kufanele lithambekele kancane libheke emlonyeni wokungena (Fig.B).Qinisekisa ukuthi ipayipi lokungena licwiliswe ngokuphelele futhi livalwe.

Ukupakisha

ibhokisi lezinkuni, ibhokisi lekhekheba lezinyosi, noma ibhokisi lebhokisi langaphakathi elinombala ohlukile

Ezokuthutha

Impahla eyinqwaba ebaluleke kakhulu noma ukulayishwa kwesiqukathi esigcwele emachwebeni ase-Ningbo, e-Shanghai, nase-Yiwu.

Amasampula

Uma isampula libiza, kungase kube nenkokhelo;uma ufaka i-oda elisemthethweni, cabangela imbuyiselo yenkokhiso.

Ungahlola ukuthunyelwa kwesampula ngomhlaba, ulwandle, noma ngomoya ngendlela othanda ngayo.

Isikhathi sokukhokha

Ithemu ye-T/T: 20% idiphozi ngaphambi kwesikhathi, ibhalansi engu-80% iqhathaniswa nekhophi ye-bill of lading

Itemu le-L/C: ngokuvamile liyakhokhwa lapho libonwa

Itemu ye-D/P, idiphozithi engu-20% kusengaphambili, ibhalansi engu-80% ye-D/P lapho uyibona

Umshwalense wesikweletu: 20% wenkokhelo ephansi kuqala, ibhalansi engu-80% ye-OA ezinsukwini ezingama-60 ngemuva kokuba inkampani yomshwalense isinikeze umbiko

Iwaranti

Isikhathi sewaranti yomkhiqizo yizinyanga eziyi-13 (sibalwe kusukela ngosuku lokulayishwa kwemali).Uma kunenkinga yekhwalithi yokukhiqiza okungeyomhlinzeki ngesikhathi sewaranti, ngokuya ngezingxenye nezingxenye ezisengozini, umphakeli kufanele abe nesibopho sokuletha noma ukushintshwa kwezingxenye zokulungisa kulandela ukuhlonza okuhlanganyelwe kanye nesitifiketi sezinhlangothi zombili.Akukho kukhulunywa ngezesekeli kwikhotheshini yempahla evamile.Ngokwempendulo yangempela, sizoxoxisana ukuze sinikeze izingxenye ezisengozini yokunakekelwa phakathi nesikhathi sonke sewaranti, futhi ezinye izingxenye zingadinga ukuthengwa ngezindleko.Ungahambisa noma yiziphi izinkinga zekhwalithi ukuze ziphenywe futhi kuxoxiswane ngazo.